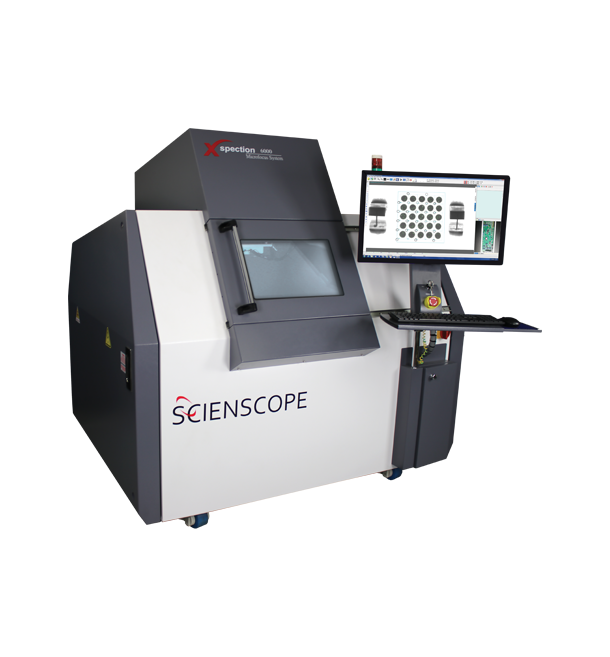

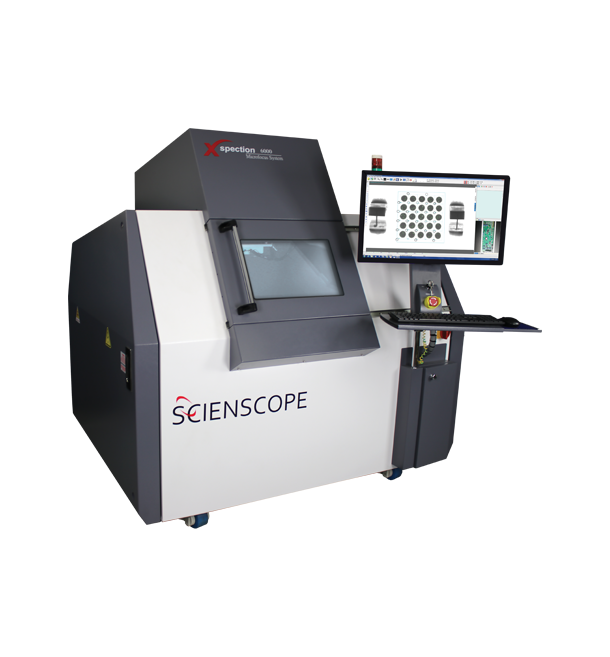

X-Spection 6000

The X-SPECTION 6000 is our most technologically advanced X-Ray Inspection System. As with all X-SCOPE platforms, it

includes every advanced s/w tool required for a wide variety of applications. With more tilt and a rotating work table, the

X-SPECTION 6000 is the ultimate in flexibility.

Applications:

- Multilayer PCBs

- BGA, QFN, wire bond, etc.

- Semiconductor

- Over molded electrical connectors

- Encapsulated components

- Aluminum die casting

- Molded plastic

- Automotive assemblies

- Medical devices

- Pharmaceuticals

- Ceramics

- Agriculture

Featuring:

- Fully integrated, 130kV high power micro-focus closed x-ray tube

- Spot size down to 5μ

- 5” x 5“ or 4” x 3“ high resolution and ultra resolution CMOS digital flat panel image detector

- 55° camera tilt for oblique angle viewing

- 22” x 18” Inspection stage with 350° rotation

- Color mapping camera with zoom window provides easy location and identification of faults

- Z axis movement of the x-ray tube and detector

- Computer controlled kV and mA settings

- Computer controlled variable speed X-Y stage (and rotate)

- Simple point and click, intuitive GUI provides access to create advanced inspection routine

All software tools are standard including (but not limited to)

- BGA Void detection and automatic calculations

- Easy macro recording for intuitive step and repeat programming

- Various measuring tools for radius, area, perimeter, etc.

- Industrial PC with Windows 10, 24” LCD flat panel display

Send en forespørgsel